What contaminants are affecting your oil? What internal issues are affecting your machines? Do you know which machines or systems will break down next? Do you wish your industrial equipment was more reliable?

Professional oil sampling and oil analysis companies can answer all of these questions, extending the life of your critical equipment and helping you stay ahead of maintenance and potential shutdowns. Improve the reliability of your equipment, eliminate unnecessary inspections and control oil consumption costs by having PetrolinkUSA sample and test your lube oil and complete a thorough walk down of your facility.

What are we looking for when we perform oil analysis services? The specific contaminants we discover can tell us how degraded your lubrication system is and what types of mechanical or electrical problems might be contributing. It will also help us determine what type of flushing and cleaning services your systems and machinery may need.

Fluid Analysis Services

We provide the following analysis services:

- Full oil sampling analysis results within 24 hours—Performed by an unbiased third-party.

- Spectrochemical analysis: 24 metals done via ICP method, Total Acid Number (TAN), viscosity at 40 degrees Celsius and water by Karl Fischer.

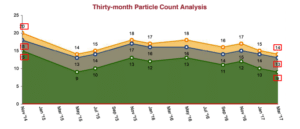

- Particle Count Analysis: Industry Standard Test for determining solid contamination levels in oil—Given as a 3-digit ISO Code Reading based on actual counts at the 4-, 6- and 14-micron levels.

- Web-based access to analysis reports and system profiles.

- Ultra clean bottles for testing—To contain less than 1 particle greater than 10um per milliliter of fluid. Specified by ISO 3722 and are a part of ISO 17025 Audit Standards at our laboratory.

- Proper bottles, head space and ullage in the bottle to provide a data effective sample.

- All technicians and employees MLA trained and certified as specified by ISO 1846-4, Sub-Part I.

- Prompt turnaround time on all samples to include same-day shipping of samples and processed/reported within 72 hours of shipping.

- Service Priority List to Customer to identify any and all out-of-spec systems and the required maintenance actions necessary to get the system back within spec.

- New Lube Reference Samples to be pulled twice a year to ensure your system has an accurate data depiction of the oil you are currently using.

| Tests We Conduct | |

|---|---|

|

|